Price 1343 आईएनआर/ Foot

MOQ : 20 Millimeters

Specification

- शेप

- Rectangular Grating

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- तापमान

- सेल्सियस (oC)

- ग्लास टाइप

- E-Glass

- उपयोग/अनुप्रयोग

- Chemical Plants, Offshore Platforms, Power Plants, Water Treatment, HVAC Ramps

- कोटिंग का प्रकार

- UV Resistant/Corrosion Resistant

- मोटाई

- मिलीमीटर (mm)

- मटेरियल

- Fibre Reinforced Plastic (FRP)

- एप्लीकेशन

- Industrial Flooring, Platforms, Walkways, Stair Treads, Trench Covers

- तकनीक

- Moulded Process

- सतह का उपचार

- Anti-Slip Coated

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- Open Area

- Approx. 68%

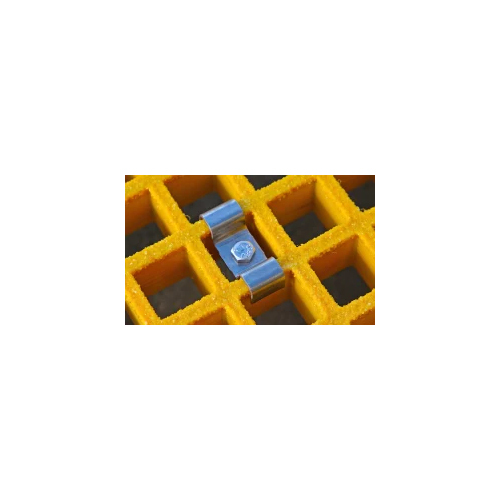

- Installation

- Easy to Install and Cut

- Fire Retardant

- Available

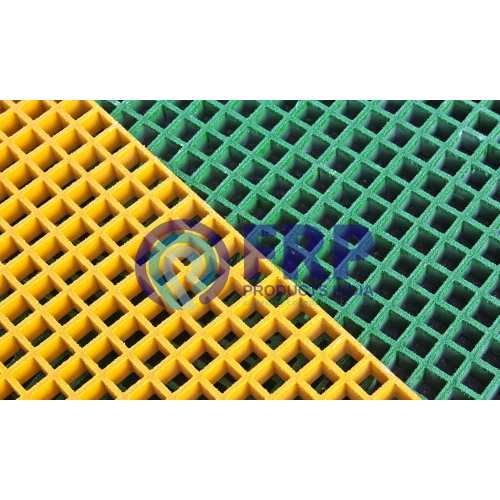

- Color

- Green, Grey, Yellow, Customized

- Weight

- Approx. 12.5 kg/m²

- Corrosion Resistance

- Excellent against Chemicals and Moisture

- Finish

- Smooth/Concave Surface

- Electrical Conductivity

- Non-Conductive

- Load Bearing Capacity

- High, Designed for Heavy Loads

- Lifespan

- Long Service Life (>20 years)

- Edge Type

- Capped or Uncapped

- Standards

- Meets ASTM E-84 & ISO Norms

Trade Information

- Minimum Order Quantity

- 20 Millimeters

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

-

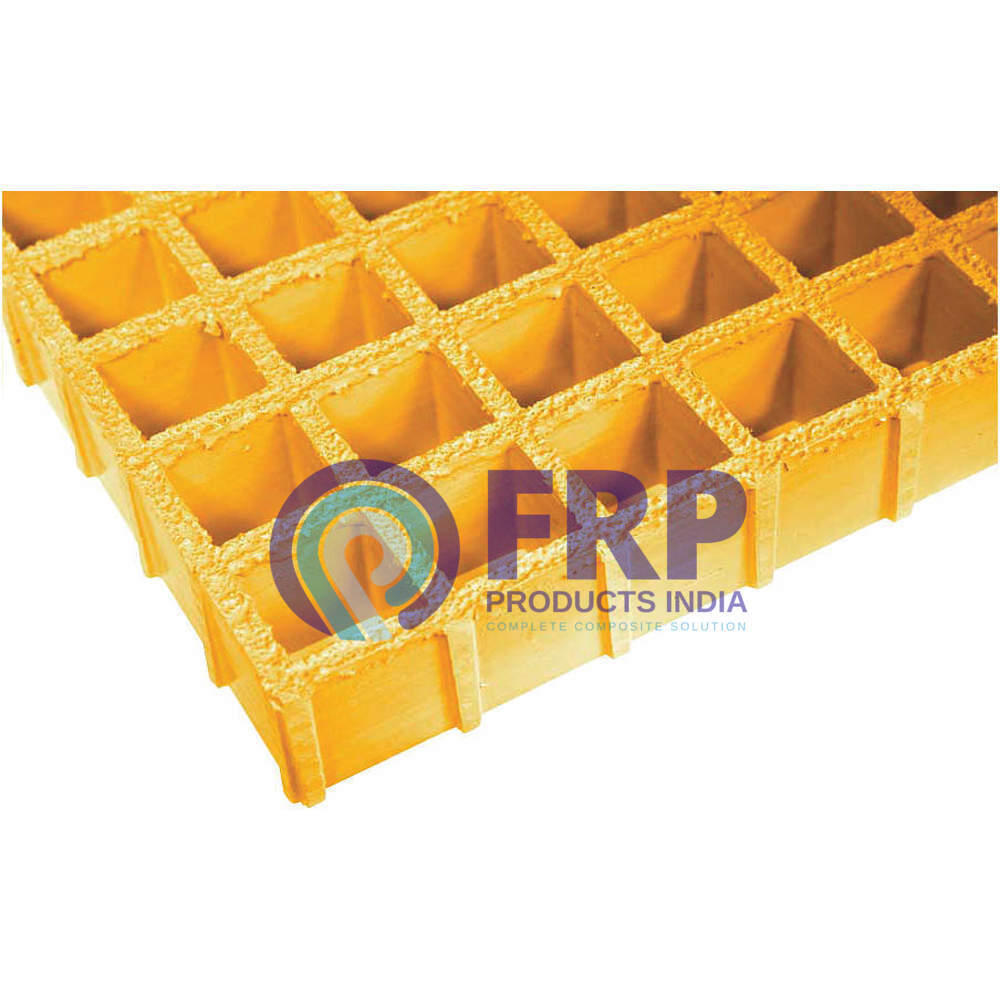

Type: Moulded FRP Grating

-

Thickness: 25mm, 30mm, 38mm (custom sizes available)

-

Mesh Size: Standard 38mm x 38mm (others on request)

-

Surface: Concave / Grit Top / Smooth

-

Colors: Green, Yellow, Grey, or as per client requirement

Engineered for Heavy Loads and Durability

Our FRP moulded grating is specifically designed for high load-bearing applications, making it a reliable choice for industries such as chemical plants, offshore platforms, power plants, and HVAC ramps. Its robust structure and E-glass reinforcement ensure stability and a long service life, enduring temperatures from -40C to 120C.

Comprehensive Safety and Compliance Features

The grating offers unmatched safety with excellent corrosion resistance, anti-slip surface, and fire-retardant properties where required. The product meets ASTM E-84 and ISO standards, ensuring it is up to the mark for use in critical and regulated environments. Its non-conductive nature enhances electrical safety.

FAQs of FRP MOULDED GRATING IN AHEMDABAD:

Q: How is FRP moulded grating installed, and can it be cut to size on-site?

A: Installation of FRP moulded grating is straightforward due to its lightweight construction. It can be easily cut, drilled, and fitted on-site to meet specific size requirements. Both capped and uncapped edges are available to suit various installation preferences.Q: What benefits does FRP moulded grating offer compared to traditional steel grating?

A: FRP moulded grating provides superior corrosion resistance, non-conductivity, and a much lighter weight than steel. It also features a non-slip coated surface, excellent fire retardancy, and requires less maintenance, leading to a longer service life.Q: When should I choose a customized color or finish for FRP grating?

A: Customized colors or finishes are ideal when your project requires branding consistency, specific aesthetic preferences, or enhanced visibility (such as safety yellow). Both smooth and concave anti-slip finishes are available to address varying slip resistance needs.Q: Where can this type of grating be used most effectively?

A: FRP moulded grating is highly versatile and well-suited for industrial flooring, walkways, stair treads, trench covers, and platforms, especially in harsh chemical environments, power plants, offshore locations, and water treatment facilities.Q: What is the typical lifespan and maintenance requirement for this grating?

A: With a design life exceeding 20 years, the FRP grating demands minimal maintenance. Its anti-corrosion, UV-resistant, and anti-slip properties ensure longevity even in challenging conditions, greatly reducing maintenance frequencies.Q: How does the grating perform in extreme temperature and chemical environments?

A: Engineered with E-glass and high-quality FRP, the grating maintains structural and chemical integrity between -40C and 120C. Its superior corrosion resistance makes it ideal for environments with aggressive chemicals and moisture exposure.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें