Price 1343 आईएनआर/ Millimeter

Specification

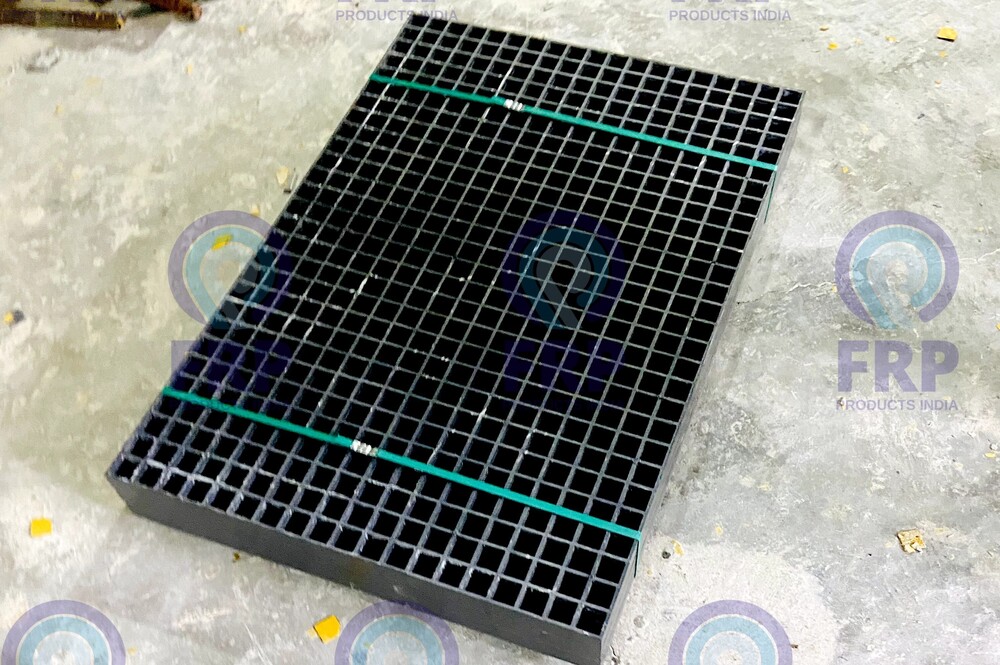

- कोटिंग का प्रकार

- Epoxy Coated

- शेप

- Rectangular

- तापमान

- सेल्सियस (oC)

- मोटाई

- मिलीमीटर (mm)

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- जीएसएम

- 350 – 450 GSM

- ग्लास टाइप

- E-Glass

- उपयोग/अनुप्रयोग

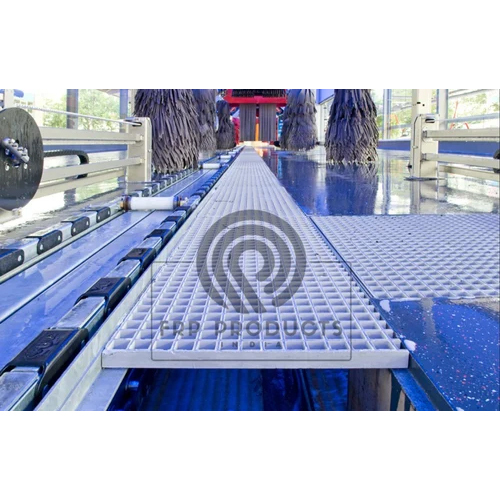

- Heavy Duty Drainage Grating for industrial, commercial or municipal use

- मटेरियल

- Fiberglass Reinforced Plastic (FRP)

- एप्लीकेशन

- Drainage System, Walkways, Trench Covers, Platforms

- तकनीक

- Pultrusion Moulding

- सतह का उपचार

- Anti-Slip Surface, UV Resistant

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- Load Bearing Capacity

- Suitable for Heavy Vehicular Traffic

- Life Expectancy

- Typically Over 25 Years

- Corrosion Resistance

- Excellent, suitable for harsh environments

- Colour Options

- Green, Grey, Yellow

- Water Absorption

- <0.5%

- Fire Retardant Property

- Meets ASTM E84 Class 1

- Maintenance

- Low Maintenance, Easy to Clean

- Impact Strength

- High Impact Resistant

- Installation Method

- Bolting or Fastening

- Standards

- ASTM, EN, IS Compliant

Trade Information

- Minimum Order Quantity

- 20 Meter

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

-

Lightweight & High Strength: Easy to handle and install while supporting heavy loads.

-

Corrosion & Rust Proof: Unaffected by moisture, salts, and most industrial chemicals.

-

Non-Conductive & Slip-Resistant: Safe for pedestrian and vehicular traffic.

-

Long Service Life: UV-stable and maintenance-free compared to steel or cast iron.

-

Custom Options: Available in solid-top or grating type, various colors, sizes, and load classes (light, medium, heavy duty).

Engineered Strength & Durability

Designed with fiberglass reinforced plastic (FRP) using pultrusion moulding, this heavy-duty drainage grating boasts superior load-bearing capacity and impact resistance. Its structure is tailored to withstand harsh weather, corrosive agents, and heavy vehicular movement, ensuring long-term integrity for your critical infrastructure.

Enhanced Safety & Compliance

This grating features an anti-slip surface, is UV resistant, and meets ASTM, EN, and IS standards for safety and performance. Certified fire retardant (ASTM E84 Class 1), it is suitable for environments where safety is paramount, such as industrial walkways, platforms, and municipal installations.

Versatile Application & Hassle-Free Maintenance

Adaptable to various settingsdrainage systems, trench covers, or platformsthe FRP grating is easy to install using bolts or fasteners. Its epoxy coating and dense, impermeable structure keep maintenance to a minimum while resisting stains and debris.

FAQs of FRP DRAINAGE GRATING HEAVY DUTY:

Q: How is the FRP drainage grating installed in a heavy-duty application?

A: The FRP drainage grating can be installed by bolting or fastening directly to existing support structures. This method offers secure placement for high-traffic areas, and the process is straightforward, minimizing downtime during installation.Q: What benefits does the anti-slip surface provide in wet or oily environments?

A: The anti-slip surface enhances pedestrian and vehicular safety by reducing the likelihood of slips and accidents, even when the surface is exposed to water, oil, or other hazardous substances. This makes it a superior choice for drainage areas and industrial walkways.Q: When is it ideal to use FRP grating instead of traditional metal grating?

A: FRP grating is ideal when you require corrosion resistance, fire retardance, and reduced maintenanceespecially in environments exposed to chemicals, water, or fluctuating temperatures. Its lightweight nature and high impact strength make it preferable over metal in many heavy-duty applications.Q: Where can the FRP heavy-duty drainage grating be used?

A: This product is suitable for industrial, commercial, and municipal drainage systems, trench covers, walkways, and platforms. Its robust design supports heavy vehicular traffic, making it excellent for parking lots, factories, and roadways.Q: What is the typical lifespan and maintenance requirement for this grating?

A: The FRP drainage grating typically lasts over 25 years due to its rust-free, UV resistant, and chemical-resistant construction. Maintenance is minimalroutine cleaning with water or mild detergents is generally all that is needed to keep it in optimal condition.Q: How does the grating perform under extreme temperatures?

A: With an operational temperature range from -40C to +120C, the FRP grating maintains its structural integrity and load-bearing capacity under both freezing and high-heat conditions, making it reliable for diverse climates.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें